As the games begin, take a tour of a bat factory with cricketer Suresh Raina

Ahead of the Indian Premier League, cricket bat connoisseur Raina visited the SG factory in Uttar Pradesh where most of India’s top cricketers get their bats. See what goes into making each blade, and watch as Raina looks back on his own first bat, which was made here too.

Suresh Raina is in his version of heaven. It’s noisy. There’s the dense rhythm of hammers hitting wood and a constant, shrill whine of sawing machines.

A month before the Indian Premier League (IPL) is scheduled to begin, Raina, a man regarded as an obsessive maestro of bats by his teammates, is at the Sanspareils Greenlands or SG factory in Partapur, a small industrial town in Meerut. He means business. For any batsman, this is the first step before a season of cricket — finding the perfect bat. And Raina, who plays for the Chennai Super Kings (CSK), will spend the better part of a day doing just that.

“Don’t ask me how many bats I am going to take from here. If my teammates find out, they will raid my kit bag. It’s the usual thing for me; I always have to keep my kit bag under lock and key during tournaments,” Raina says over the whine and rat-tat-tat, before he wanders off, as he will do many times during this conversation, to consult on minute changes with the artisan making his bat.

Last year was transformative for the 34-year-old batsman. In August, he announced his retirement from international cricket moments after his CSK captain MS Dhoni did. Raina had played 226 ODIs, 78 T20Is and 18 Tests for India.

Then, in September, there was his much-publicised exit from the IPL bio-bubble in the UAE before the tournament began (Raina has maintained that he left because of a death in the family). Now, one of CSK’s most iconic players and the second-highest run-scorer in the history of the IPL (after Virat Kohli) is finally ready to play some cricket.

But first, it’s time to geek out over the art of bat-making. Raina is generous with his expertise and speaks rapidly and in detail, explaining things like ping, grain, knock, spring, cleft, balance and blade shapes. But in the end, he says, the most important thing is something that cannot be quantified — “feel”.

“Like you may talk to your beloved, I talk to my bat,” he says, only half joking. “Eyes closed, I sit with it. I ask questions, I seek answers. If a bat suits you, you will know the moment you hold it. The first few knocks with the ball, the sounds it creates, its swing… you will just know that it is the one.”

BLADE RUNNERS

The feel of a bat may be highly subjective, but there’s nothing abstract about the way the modern bat is made.

Raina is now standing in the quietest corner of the factory, looking over the shoulder of a middle-aged man with greying hair and thick glasses, hunched over a pentagon-shaped wooden block called a cleft. Bats for professional cricketers are made with the wood of the English willow. After a tree is felled, it is cut into clefts and exported from England to manufacturers.

This artisan Raina is watching is Prempal (he goes by only one name) and he’s been making bats at SG for 32 years. He is scribbling, directly on the cleft, measures that will be used to turn it into the blade of a bat. Prempal has made bats for Sunil Gavaskar, Mohammad Azharuddin and Rahul Dravid, among others. Now his bats are used by Raina, Rishabh Pant and Hardik Pandya. He knows the personal preferences of each player.

What he’s doing now is grading the clefts according to the texture and consistency of the grain — the lines that appear in a tree’s bark as it ages. More grain means the wood is more compact, harder and heavier. Even a cleft’s moisture content is important (it should ideally be between 8% and 15%) if it is to hold its own through repeated use.

“Some players use bats with less grain while some like MS (Dhoni) and Sachin (Tendulkar) prefer bats with more,” Raina says. “Some of the top-order batsmen like (Cheteshwar) Pujara play with the lighter bats. If you like to score fast, with big shots, you will pick a heavier bat.”

Raina himself likes lighter bats — “Waisa mera body bhi nahi hai (I don’t have the physique) of those bulked-up types who look like they can consistently thwack the ball for sixes.”

There are a lot of things for Prempal to consider while inspecting a cleft: if he has a fat block, he can craft a thick spine — the distinctive curved back of the blade — and thick edges too. For Raina’s bat, he wants evenly spaced grain.

“If it’s a narrow grain, the bat might just play well but it will not last long. This is the first step and the most important one. Here, we decide if a cleft is good enough for an international player,” says SG’s managing director Paras Anand, whose grandfather started the company in the 1930s.

T20 cricket heralded a big change in how bats are made, Anand adds. They are made for aggressive, hit-it-out-of-the-park batting now. “If you look at the bats today, they have a lot more wood at the back.”

SWEET SPOTS

Once the cleft has been graded, it’s time to shape it into the curved blade. A bat’s blade can be roughly divided into three parts — the shoulder, the middle and the toe. It’s the middle section that has the most muscle , the thickest part , and offers the greatest rebound (ping) and power. It’s here that the famous sweet spot lies.

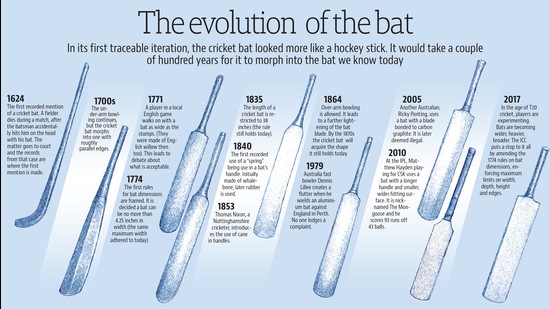

During the early years of T20 cricket, players experimented with wider, heavier and broader bats, effectively maximising the area of the sweet spot. In 2017, the International Cricket Council (ICC) announced new bat regulations to curb this development.

“The blade of the bat shall not exceed the following dimensions: Width: 4.25in / 10.8 cm, Depth: 2.64in / 6.7 cm, Edges: 1.56in / 4.0cm,” the new rules state, while “the overall length of the bat, when the lower portion of the handle is inserted, shall not be more than 38 in/96.52 cm.” Bat makers must now improvise within those dimensions.

“The sweet spot more often than not lies 4 inches from the toe, till about 8 inches into the blade,” Paras says. “It is determined by how much wood you have on the back of the bat. If the maximum wood is at the lower end of the bat then the sweet spot will move slightly lower but if the maximum wood is slightly higher, then the sweet spot moves up.”

Batsmen change the kind of bat they use depending on the conditions and tournaments they are playing. When Indian cricketers travel to Australia, where there is more bounce, they pick bats where the sweet spot is placed higher than in the bats they would use on the subcontinent.

Bats can’t just be made thicker and heavier for better hitting. The balance of the bat, the consistency of the wood, and how comfortable a player feels with the weight are all equally important.

“I have always used 1180 to 1200 gm bats,” Raina says.

Somebody in the top order, who is more likely to play the fast bowlers with soft hands, would ideally play with bats that weigh 1130 to 1140 gm, Anand adds. “That 40-gm weight difference is massive for a batsman. The elite players are so used to their bats’ weights that even if you give them 5 gm extra, they will know.”

After the cleft is cut into a blade’s shape, it is hard-pressed with machines and knocked with mallets to check whether the ping of bat is good — something that needs a master artisan’s feel to gauge.

THE HANDLE BAR

Now that the blade has been made, it’s time to consider the handle. “There’s no one specification for a good handle. Some players use long handles, some want them oval or tapered. It all depends on how a player wants to hold it,” Raina says. “I use an oval handle. It’s thick because my palms are large.”

Whatever the shape, the top-of-the-line handles are made of Sarawak cane imported from Malaysia (the ICC allows only wood, cane and rubber to be used in handles). For elite players, SG uses nine strips of cane and thin strips of rubber glued together for the bat’s handle, with a cotton thread wound over at a set tensile strength.

“This generates the effect of a spring,” Raina says. “It generates more power and stability. The ball travels farther because of the higher number of cane strips. They absorb the shock when the ball hits the bat, ensure that bat does not lose too much of its stability, and this makes it easier to direct the ball too.”

Raina’s first proper bat came from this factory. He was 12 years old when his father enrolled him in a coaching centre and bought him an SG bat. He doesn’t have that first bat anymore, but Raina is a bat collector. He has over 100 and often battles with his family about where to store them.

“I have kept a few old ones, like the one with which I scored a century on debut, signed by Sachin (2nd Test, India’s tour of Sri Lanka, 2010 — a 200 partnership with Tendulkar),” he says. “Then the one with which I won my first Man of the Match award (vs South Africa, 2010 ICC T20 World Cup, first Indian T20 centurion).”

“I will take 10 to 15 bats for the IPL and use them all,” Raina adds. “I know the sound of all my bats.”